The following details outline a highly efficient, semi-automated cocaine production setup within a “Schedule 1” context, focusing on maximizing output with minimal manual intervention in a dock warehouse and barn environment. This system, while not fully autonomous due to inherent limitations, aims for near hands-free operation across coca plant cultivation and cocaine processing stages, making it suitable for large-scale endeavors.

How to Fully Automate Dock Warehouse

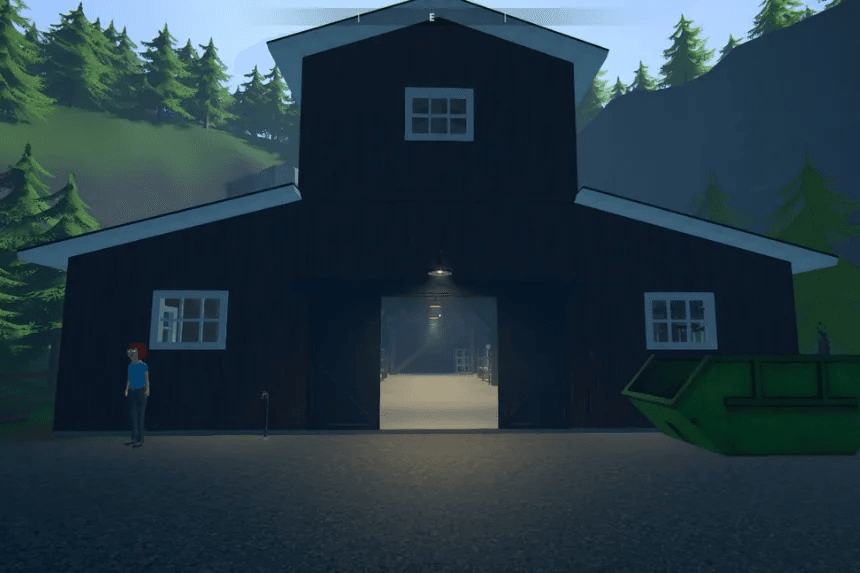

This dock warehouse and barn setup is one of the most efficient semi-automated cocaine production builds currently achievable in Schedule 1. While some manual tasks remain, the majority of the system runs hands-free, making it ideal for large-scale operations.

Phase 1: Coca Plant Production Setup

Staffing Requirements

- 8 Botanists

- 1 Cleaner

Warehouse Layout

- Storage & Beds:

- Overflow storage racks repurposed from a dismantled meth lab.

- Four soil storage racks.

- Eight drying racks for dried leaves, each paired with a dedicated output rack.

- A total of 24 growing pots.

- Sleeping quarters set up for all workers with a few spare beds included.

- Overflow storage racks repurposed from a dismantled meth lab.

Automation Steps

- Assign Botanists:

- Each botanist is assigned to one soil supply rack.

- Three pots are designated to each botanist to maintain efficient workload distribution.

- Each botanist is assigned to one soil supply rack.

- Growing & Drying Workflow:

- Each group of three pots is linked to a specific drying rack.

- Botanists are assigned to their corresponding drying racks, ensuring harvested cocoa leaves are automatically transferred for drying.

- Each group of three pots is linked to a specific drying rack.

- Drying Rack Configuration:

- All drying racks are set to “Quality: Gold”.

- Dried leaves are then routed to the storage racks beside each drying unit.

- All drying racks are set to “Quality: Gold”.

- Cleaner Setup:

- The cleaner is assigned to manage three strategically placed bins that cover the entire workspace, ensuring cleanliness and efficiency.

Phase 2: Cauldron Cooking in the Barn

Required Equipment

- 8 Cauldrons

- 8 Labs

- 22 Storage Racks (Including overflow and future-proofing for brick pressing)

Staffing Requirements

- 8 Chemists

- 2 Handlers

Each chemist is assigned to:

- One cauldron

- One lab station

- One nearby bed

This one-to-one assignment maximizes processing speed and minimizes walking distance.

Handler Logistics

- Two handlers are used to transport gasoline from four large storage racks to the cauldrons.

- Each handler is assigned multiple routes to ensure all cauldrons receive the necessary fuel supply.

Production Routing

- Cauldron to Lab:

- Each cauldron is linked to the nearest lab station to streamline the transfer of processed cocoa paste.

- Each cauldron is linked to the nearest lab station to streamline the transfer of processed cocoa paste.

- Lab to Storage:

- Lab output is directed to designated storage racks.

- Overflow racks are placed nearby for manual transfer when necessary.

- Lab output is directed to designated storage racks.

Limitations & Optimization Ideas

- Worker Limit: With a cap of 10 workers in the barn, full automation is limited. To improve this:

- Chemists could potentially be assigned to multiple stations to free up space for additional handlers.

- Additional handlers could automate overflow transfers.

- Chemists could potentially be assigned to multiple stations to free up space for additional handlers.

- Manual Tasks:

- Gasoline restocking is not automated but rarely needed due to the low consumption rate.

- Overflow storage management and final mixing processes are still manual but may be optimized in future builds.

- Gasoline restocking is not automated but rarely needed due to the low consumption rate.